Azico Biophore research focuses on the notion of integrated product development, which meets all of the product needs of our API Company. To accomplish this, we have a well-equipped R&D center with all of the necessary infrastructure, equipment, and experts in the field, including 100+ scientists who are always working on new product introduction, process innovation, and analytical research simultaneously.

- State of art Kilo Level cum Pilot Plant complying to cGMP requirement with its dedicated clean room areas up to packaging of final products.

- Approved/Inspected by USFDA (USA), TGA (Australia), ANVISA (Brazil), COFEPRIS (Mexico), WHO-GMP, EU-WC (CDSCO), GMP & GLP (DCA) and ISO 9001: 2015, 45001 : 2018 & 14001:2018.

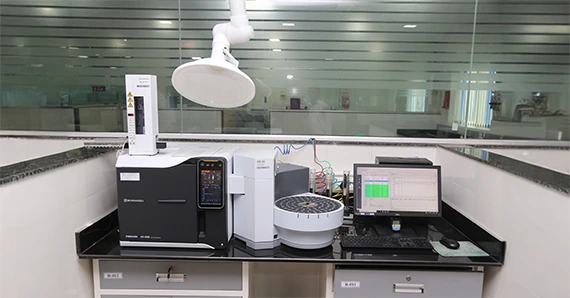

- R&D laboratory is fully equipped for Milligram to kilogram level scale up of APIs and APIs intermediates.

- R&D facility is equipped with international standard fume hoods and walk-in types fume hoods, hydrogenators and other equipment to perform all types chemical reactions.

- Development of Generic APIs for Regulated markets of both Niche Small volume to moderate to high volume.